1 / 1

Glass Fiber Cloth, PA, PE, PP Laser Cutter for Filters

| Model No. : | CJG-250400LD |

|---|---|

| Brand Name : | Golden Laser |

| Machine Type : | Laser Cutting Machine |

Ürün Açıklaması

Glass Fiber Cloth, PA, PE, PP Laser Cutter for Filters

This laser cutter is specially for cutting filter fabric, nonwoven, glass fiber cloth, PE composite materials. But also perfect cut more industrial soft fabric, such as dustproof cloth, wipe fabric, insulated material, coated fabric, textile, gauze, geotextile and more.

Filter material cutting with laser technology by GOLDENLASER

Automated processes with laser system - Higher productivity, more economical working - save time and cost.

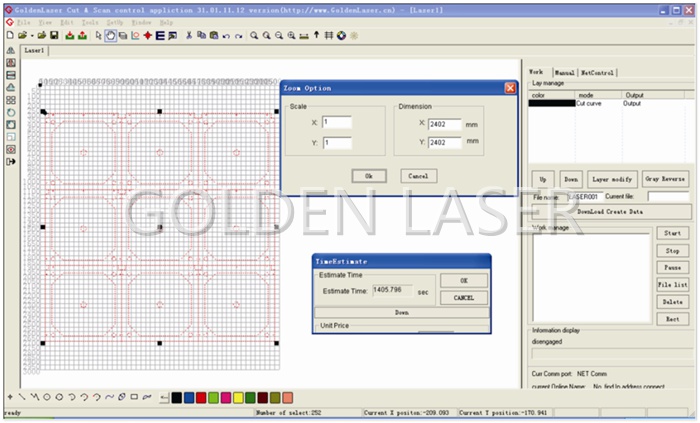

Any kind of design can be estimated production, our software support .dxf .ai .plt extension file. So if you have any question please feel free to contact with us! We will recommend the best machine for you.

Laser machine can be customized exactly to the needs of your application through the modular design of our laser systems. You will receive from us a laser system specially configured for your requirements and designed to meet your needs.

Compared with traditional (heat) blade cutting, Laser has some remarkable advantages

1. No mould --- fast, no waste on moulding

2. Save labor cost --- reduce the cost and risk on employees

3. Clear of cutting edge

4. Higher efficiency --- the cutting speed can reach 350mm/s (21m/min)

5. No tool wear --- save consumable cost

Why Laser Cutting in Filter Industry

- Automatic sealing of cutting edges prevents fringe

- No tool wear - no loss of quality

- Complete exhaust and filtering of cutting emissions possible

- High precision and accuracy of repeatability

- Automated production process with conveyor and feeding systems

- Marking systems in various variants

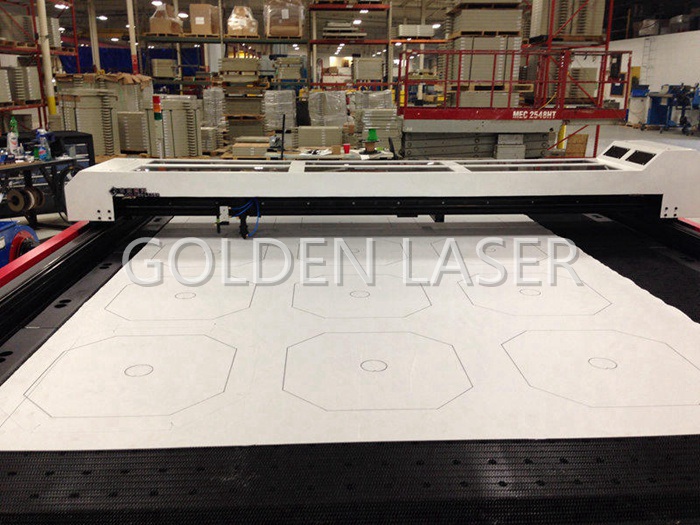

Laser Cutting Machine for Filter Cloth Production

LASER CUTTING TECHNOLOGY FOR OPTIMAL RESULTS

Here precise filter cloth shapes are created via CAD software and transferred to the high-speed laser cutters.

As a result, you are assured high speed, superior cutting, sealed edges and the quality demanded – consistently – of world-class filter cloth.

Contact us to learn more about GOLDEN LASER's state-of-the-art filter cloth laser cutter, contributing to your competitive advantage.

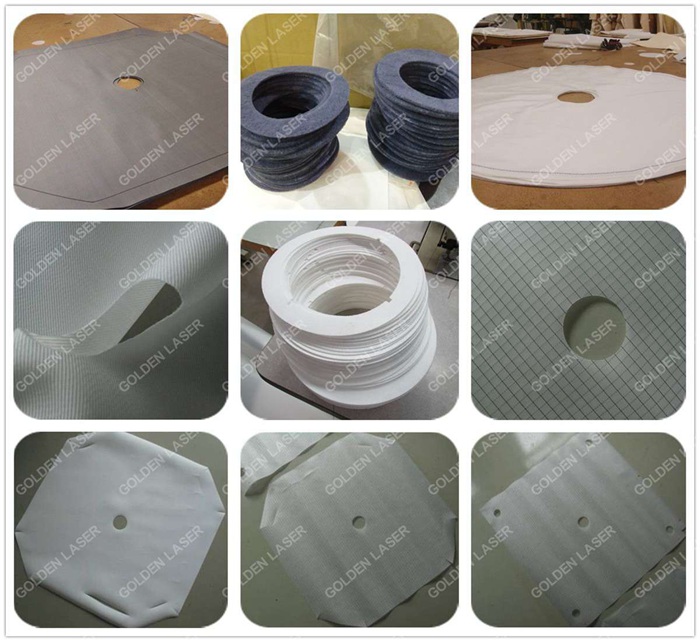

Laser cutting of filters, filter cloth, filter materials, filter mats, filtration medias

Filter cloth comfortably cut to any size

› Automatic sealing of cutting edges. No fraying of the cloth› No tool wear – no loss of quality

› High precision and accuracy of repeatability

› Automated production process with conveyor and feeding systems

› Intelligent graphic design and nesting software, easy to use. Available for cutting any graphics and shapes. (Compatible with a variety of graphics format)

› Automatic switching of marking system and laser head emitting beam. Perforation, marking and cutting all in one step.

› Filter cloth cutting edges can be customized, cloth edges lifetime can be set as required.

› Vacuum adsorption working table, prevention of cloth edges crimping or warping.

› Complete exhaust and filtering of cutting emissions possible

› Optional fully enclosed structure to ensure the cutting dust does not leak, suitable for operation in the intensive production plant.

Filter material dust-free cutting by laser

Precisely cut almost Any Kinds of filter materials in Any Shapes

Typical filter media are: Polyethylene (PE), Polypropylene (PP), Polyester (PES), Polyamide (PA), Fibre glass, Non-woven, Fabric, Paper, Felt, PTFE, etc.

Nonwoven Laser Cutting Machine for Filter Cloth

|

|

Laser Cutting |

Traditional Heat Blade |

|

Working flow |

|

|

|

Conclusion |

For whole product only 1 person. No tool wear. |

For whole product usually 4 persons. Tool wear around 7-14days. |

Marker Pen

User-friendly Software Interface

Laser Cutting Machine Features

1. Cutting accuracy can reach 0.1mm

2. Heat treatment, automatic edge sealing with smooth cutting edge

3. Available to setting the using period of cloth edge according to requirement of user.

4. Mark pen and laser automatic switching, complete the whole process of punching, marking and cutting in one step.

5. Intelligent graphics design and nesting software, simple operation, available for cutting any shapes.

6. Vacuum adsorption working table, perfectly solve the problem of warping cloth edges.

7. Stainless steel conveyor belt, with automatic continuous feeding and collecting systems, high efficiency.

8. Fully enclosed structure to ensure the cutting dust does not leak, suitable for operation in intensive production plants.

Laser Cutting Machine Configuration

|

Model NO. |

CJG-160300LD |

CJG-210300LD |

CJG-250300LD |

CJG-250400LD |

|

Working area |

1600X3000mm |

2100X3000mm |

2500X3000mm |

2500X4000mm |

|

Laser Power |

CO2 DC Glass Laser Tube 80W / 130W / 150W CO2 RF Metal Laser Tube 150W / 200W / 275W / 400W / 500W |

|||

|

Working Table |

Vacuum absorb conveyor working table |

|||

|

Positioning Accuracy |

±0.1mm |

|||

|

Cutting Speed |

0-36000mm/min |

|||

|

Motion system |

Offline Servo motion control system, 5 inches LCD display |

|||

|

Cooling System |

Constant temperature water chiller |

|||

|

Power Supply |

AC 220V±5% /50Hz |

|||

|

Format Support |

AI, BMP, PLT, DXF, DWG, etc. |

|||

|

Standard Collocation |

550W upper exhaust fans, 3000W nether exhaust fans, Mini air compressor |

|||

|

Optional Collocation |

Auto-feeding system, Auto-recognition system, Auto nesting software, Marking system, Double laser head |

|||

|

Working area and laser power can be customized as your requirement. |

||||

Nonwoven Laser Cutting for Filter Cloth Samples

Sorgunuzu bu tedarikçiye gönderin